The Factory Orchestra: Understanding the Three Layers of RTLS Software

Walk into an empty concert hall before a performance and the silence feels charged. Every musician knows their part. Every instrument has its place. But without rhythm, harmony, and melody working together, there is no music — only noise waiting to happen. A smart factory is very similar. Machines, assets, and workers all play their […]

Geofences That Protect Quality and Your Customer’s Trust

You can have the fastest line, the best people, and the most advanced tools, but if defective products slip through, everything is at risk. Customers lose trust, money is lost in compensation, and the reputation you’ve worked so hard to build is damaged. This is where geofences in RTLS make a real difference. At DynaWo, […]

Seeing Together: How RTLS Builds Internal Transparency in Smart Factories

Transparency is important for customers or partners, but also critical for people inside your factory. In today’s connected manufacturing environments, teams rely on data as much as they rely on tools. Operators, maintenance technicians, quality engineers, and managers all need to see the same picture, in real-time, to make fast and informed decisions. That shared […]

From Open Kitchens to Open Factories: Building Trust Through Transparency

In restaurants, the kitchen was once a mystery. Diners waited behind closed doors, unsure of what was happening beyond the swinging panels. But as food culture evolved, curiosity turned into expectation. People wanted to see the process of their meals prepared. They want to witness the care, the craft, and the authenticity behind every dish. […]

Smarter Shopping with RTLS: Reducing Crowds, Increasing Loyalty

Supermarkets thrive on flow. The best shopping experiences feel effortless — customers move naturally through aisles, discover products easily, and reach the checkout just as it becomes available. But during busy hours, that flow often breaks. Crowded aisles, long lines, and delayed restocking turn convenience into frustration. Retailers have traditionally responded reactively — adding cashiers […]

Rethinking the Supermarket: How RTLS Protects Food, Saves Energy, and Improves Shopping

Supermarkets have long optimized their layouts to guide shopper behavior and boost sales. Researchers have studied how aisle design, product placement, and flow influence purchasing decisions. Yet one essential factor remains underexplored — the role of real-time location and environmental data in shaping both efficiency and experience. At DynaWo, we’ve already shown how RTLS enhances […]

Predictive Maintenance with RTLS: Keeping Factories Running, Preventing Failures

Factories today are expected to do more than produce — they’re expected to anticipate. Downtime, quality issues, and safety incidents are no longer just operational risks; they are reputational ones. Clients expect reliability, and that requires foresight. That’s where predictive maintenance comes in — and where real-time locating systems (RTLS) can quietly make the difference. […]

When the Environment Fights Back: How RTLS Protects Workers in Extreme Conditions

Some workplaces test the limits of safety. Deep underground mines, steel foundries, chemical plants, or offshore rigs — these are environments where visibility is low, heat is high, and the margin for error is thin. Traditional safety systems rely on line of sight and human judgment, but in these conditions, both are limited. That’s where […]

When Factories Think in Motion: RTLS for Sustainable Manufacturing

In a recent study, researchers raised an interesting phenomenon that many smart factories are embracing to meet the growing demand for low-carbon manufacturing: replacing traditional fuel-powered forklifts and tuggers with electric vehicles (EVs) for material handling (Zhou & Lin, 2025). It’s a powerful step toward sustainability — but it also introduces a subtle new challenge. […]

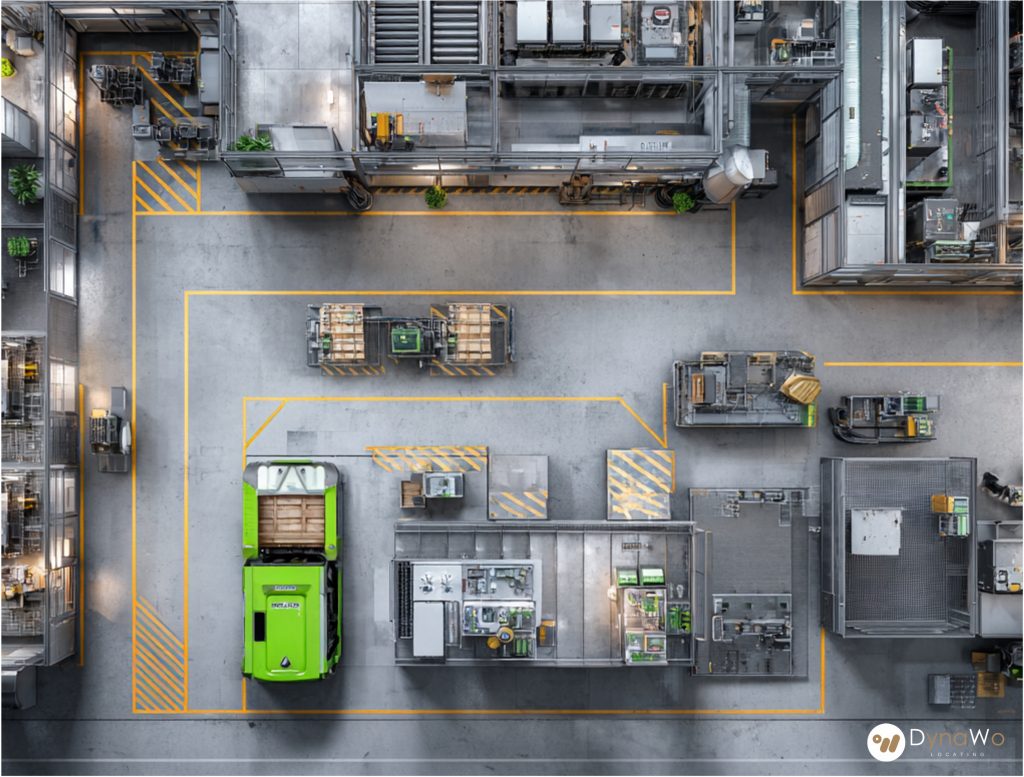

Geofences that Keep Workers Safe in Factory Danger Zones

Factories are places of productivity — but also of risk. Heavy machinery, forklifts, high-voltage areas, and chemical storage zones all create environments where a single mistake can cause serious accidents. According to recent research, many of these “major accident risk zones” remain difficult to manage, even with strict training and safety protocols (Zhou et al., […]