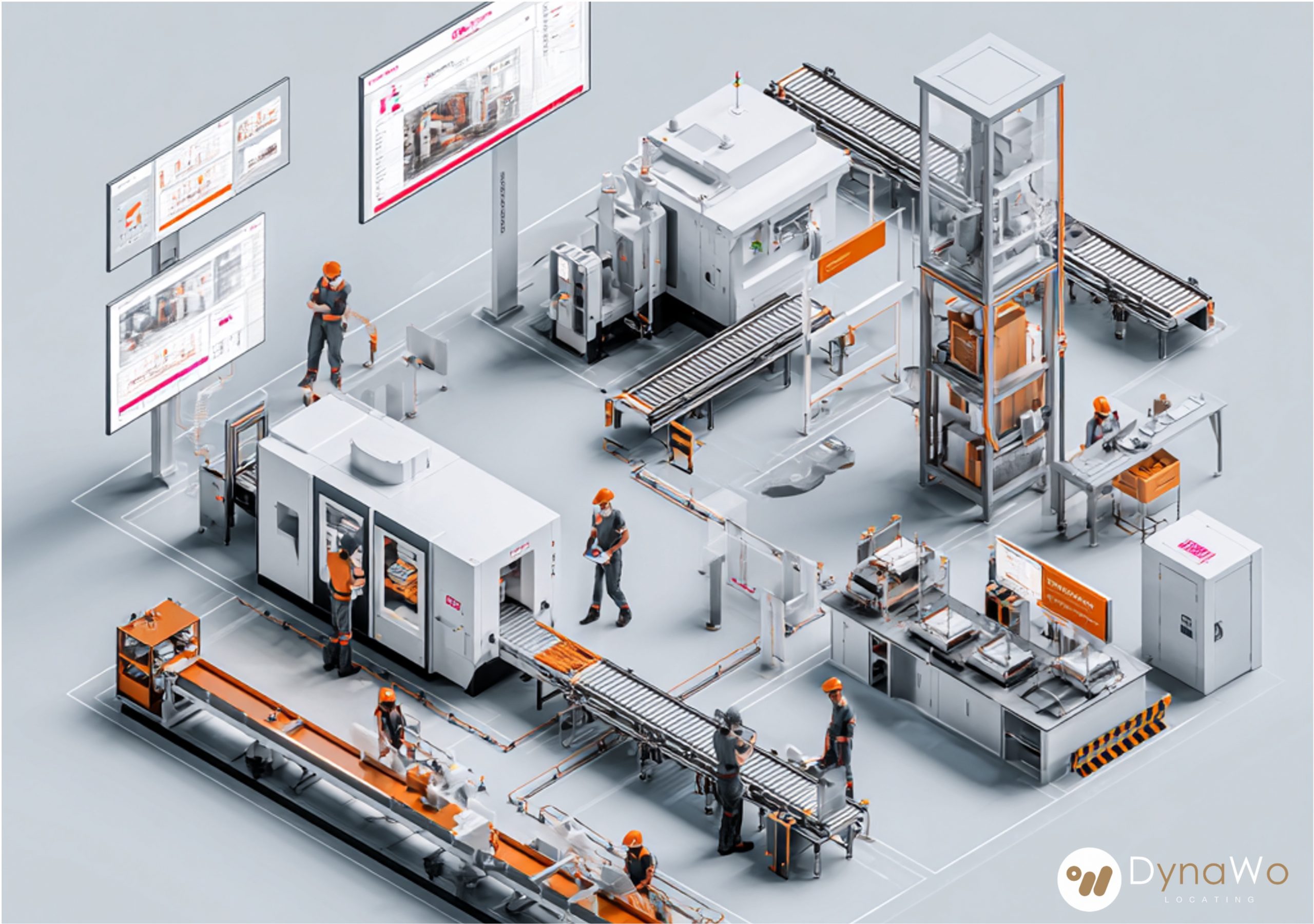

Transparency is important for customers or partners, but also critical for people inside your factory.

In today’s connected manufacturing environments, teams rely on data as much as they rely on tools. Operators, maintenance technicians, quality engineers, and managers all need to see the same picture, in real-time, to make fast and informed decisions.

That shared visibility — what we call internal transparency — is one of the most transformative outcomes of RTLS (Real-Time Locating Systems) technology.

At the heart of every RTLS setup are two simple components: tags and anchors.

- Tags are small, smart devices attached to assets, tools, equipment, or even worn by workers.

- Anchors are fixed reference points installed throughout the workspace — on ceilings, walls, or vehicles — that receive signals from tags and calculate precise location and condition data.

Using technologies like UWB (Ultra-Wideband) or BLE (Bluetooth Low Energy), these tags continuously transmit their position and sensor readings — temperature, motion, shock, or battery status — to nearby anchors. The data may then be visualized in dashboards accessible to all relevant teams. Here, RTLS becomes a shared language that generates transparency. Operators can view which equipment is active, which is idle, and which might need service soon. Maintenance crews receive live alerts when vibration sensors indicate unusual patterns. Quality engineers can verify that materials have passed through the correct process zones without manual scanning. Managers, in turn, see the whole operation unfold in real time — who’s working where, which line is bottlenecked, and how to reallocate resources efficiently.

RTLS creates the kind of internal transparency removes uncertainty. It shortens response times. It eliminates “Where is it?” from daily conversations and replaces it with “I’ve got it.”

Imagine a small situation on the floor: A machine starts showing minor anomalies in its vibration profile. The RTLS tag attached to it sends data to the nearest anchor, which instantly forwards it to the system dashboard.

- The operator sees the alert on their terminal.

- The maintenance technician, already nearby, receives the same notification on a tablet.

- The floor manager’s dashboard updates automatically, showing a yellow status icon for that zone.

Within minutes, the team coordinates a quick intervention — without phone calls, confusion, or downtime. That’s what internal transparency feels like: awareness without friction.

Internal transparency also drives cultural changes. When everyone in the factory sees the same data, it removes silos. Information is no longer something that travels up and down hierarchies — it flows sideways, openly, and usefully. Workers gain confidence in decisions because they can see what’s happening themselves. Managers earn trust by sharing insights, not withholding them. And across departments, accountability feels collaborative, not imposed.

This is how RTLS becomes more than a digital tool, but a framework for teamwork. Tags and anchors are RTLS’ building blocks that drives clarity. When everyone inside a factory can see what’s happening, they can act faster, safer, and more confidently. And that’s where true transparency begins — not on dashboards meant for outsiders, but in the quiet moments of cooperation inside the team.

At DynaWo, we design RTLS systems not only to make factories smarter and more human. Because the best technology doesn’t replace people — it helps them see together.