In a recent study, researchers raised an interesting phenomenon that many smart factories are embracing to meet the growing demand for low-carbon manufacturing: replacing traditional fuel-powered forklifts and tuggers with electric vehicles (EVs) for material handling (Zhou & Lin, 2025).

It’s a powerful step toward sustainability — but it also introduces a subtle new challenge.

In large factories with multiple workshops, these electric vehicles face limits on load capacity and battery life. They need to handle diverse delivery tasks, often on tight schedules, across expansive industrial spaces. The result is a logistical balancing act: scheduling round trips efficiently without draining batteries, delaying deliveries, or creating traffic bottlenecks inside the factory.

And that’s exactly where real-time locating systems (RTLS) come in.

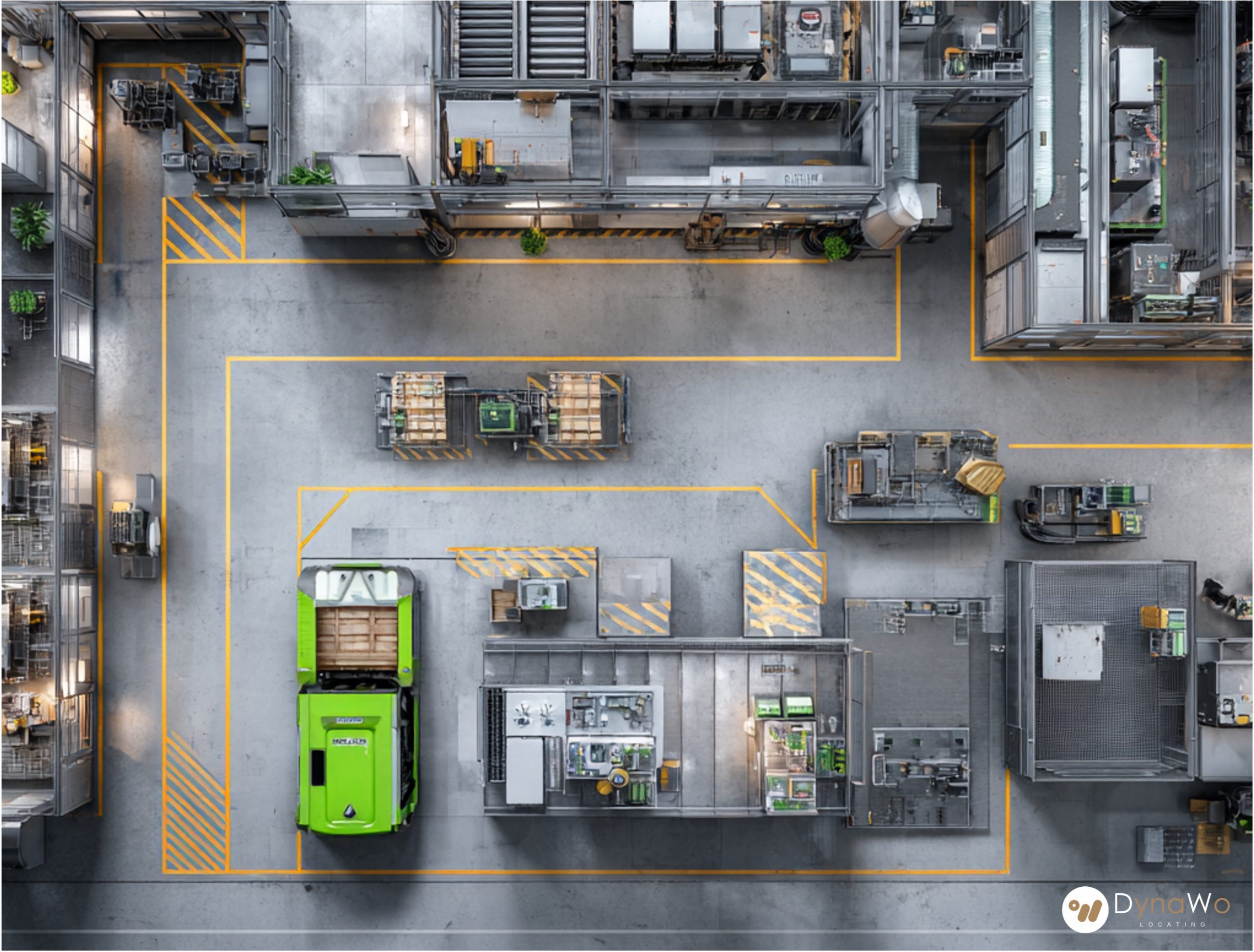

The Invisible Coordination Layer: RTLS doesn’t move materials, lift loads, or charge batteries. What it does is bring clarity. By tagging vehicles, pallets, and production zones, RTLS builds a live, digital map of the factory. It knows which vehicle is moving, which one is idle, and where each needs to go next. Instead of waiting for manual assignments or fixed schedules, tasks are coordinated dynamically. If one electric vehicle is nearing the end of its battery cycle, another one nearby can be automatically assigned and take over the task. If two vehicles are scheduled to pass through the same narrow corridor, the system can sequence them to prevent congestion. Through simple visibility, movement becomes intelligent — and every kilowatt of battery power is used with purpose.

The Rhythm of Smart Flow: Think of RTLS as the conductor of an orchestra. The instruments — the EVs — are capable on their own, but without coordination, their performance can become noisy and inefficient. With RTLS, the rhythm changes. Deliveries are assigned based on location, urgency, and capacity. Routes are shorter, waiting times drop, and idle movement disappears. Operators can see at a glance where vehicles are, what they’re carrying, and when they’ll return. Behind the scenes, this awareness adds up to smoother production, steadier energy use, and fewer interruptions. It’s not automation replacing people — it’s visibility empowering them to make faster, better-timed decisions.

Sustainability in Motion: Every minute of unnecessary travel inside a factory is wasted energy. RTLS helps stop that waste before it begins. When movements are visible, planning becomes more responsive. Battery charging stations can be positioned where they’re actually needed. Deliveries can be grouped logically instead of reactively. And the moment a vehicle completes its route, the next assignment is already waiting. The outcome isn’t just higher efficiency — it’s a cleaner, calmer kind of sustainability. Machines work less frantically, operators work with more confidence, and the entire operation uses less power to achieve more output.

At DynaWo, we see RTLS as the quiet force behind smarter, greener factories. It doesn’t make the vehicles electric or the machinery efficient — but it ensures the whole ecosystem runs in harmony.

The future of low-carbon manufacturing isn’t only about what powers your vehicles; it’s about how that power is used. RTLS gives factories the awareness they need to turn sustainability into motion — coordinated, efficient, and always in sync.

Zhou, X., & Lin, J. (2025). Scheduling optimization of electric vehicle material handling in smart manufacturing systems. Journal of Engineering Design, 36(2), 151–165. https://doi.org/10.1080/09544828.2025.2537463