Why does real-time location system RTLS matter on a live site?

Materials wander. Floors change daily. Sub-contractor crews rotate. Paper checklists and end-of-day reports can’t keep pace with what’s actually happening between the gate and the crane. RTLS — real-time location — fills those gaps without slowing the work.

How we design it — simple and practical.

- Tag what moves the schedule: containers, steel, MEP kits, high-value tools.

- Define a few smart zones: gate, yard, crane pad, floor staging, restricted areas.

- Set clear rules: “too long here,” “wrong floor,” “entered restricted zone,” “SOS raised.”

- Deliver signals by role: foreman, safety lead, logistics—not everyone.

- Keep people in control: the system alerts; your team decides and acts.

Four site-ready scenarios

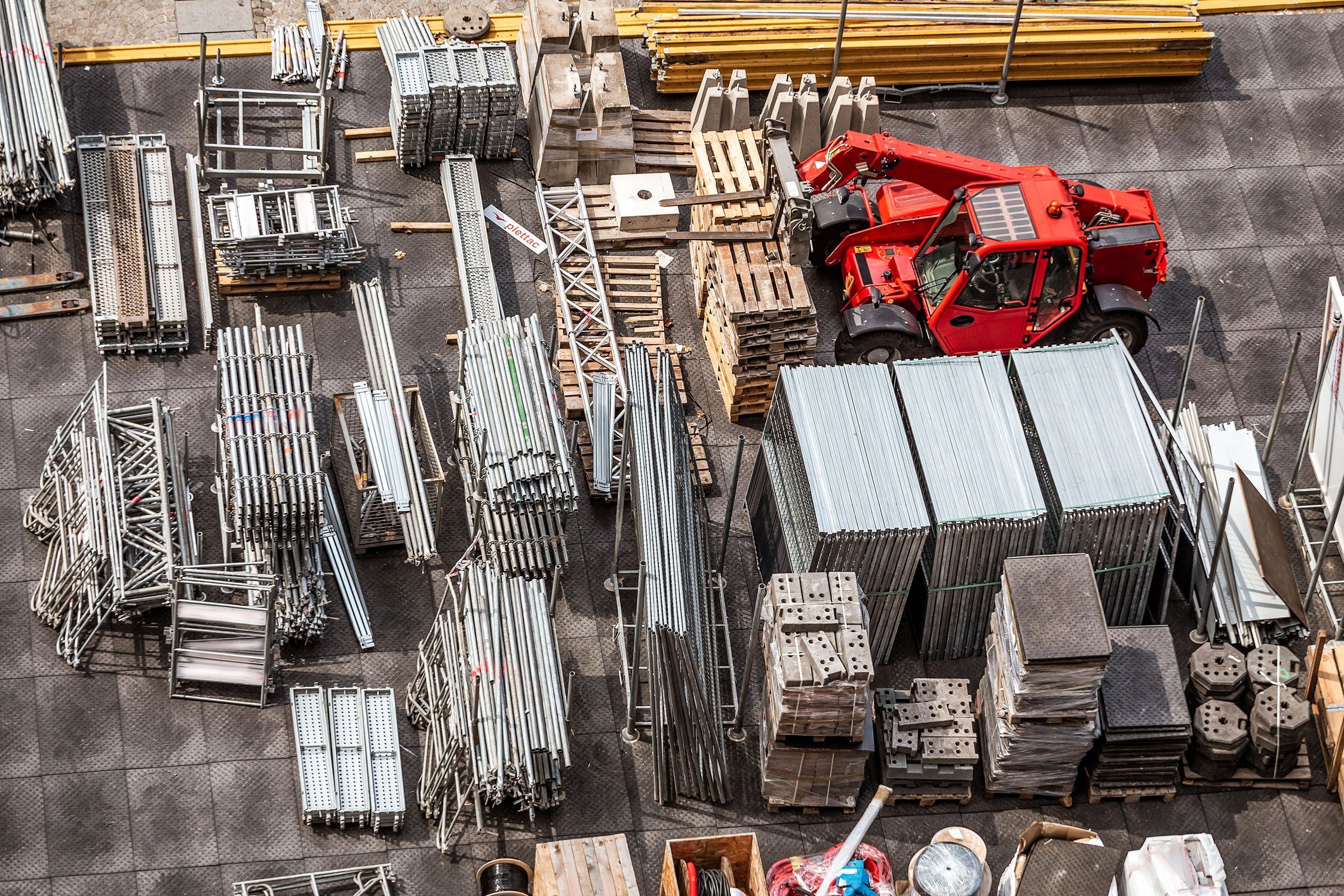

Tagging construction materials (flow without the hunt)

- Problem: Materials and tools go missing between yard and floor. Crews lose time searching; installs slip.

- Flow: Tag materials at the gate → zone reads at yard and crane → “wrong floor” alerts on arrival → staging dwell pings the foreman if a kit sits past threshold.

- Result: Faster “find and fit,” fewer re-handles, clearer handoffs between trades.

Safety of workers (respond faster, smart operations)

- Problem: When something happens, location is unclear and response scatters.

- Flow: Smart badges with a panic button send the SOS and location to the safety lead; mustering geofences show who reached assembly points during drills; no-go zones (e.g., energized rooms) raise an alert on entry.

- Result: Shorter response time, clean accountability, better drills with live headcount.

Access management (the right people in the right places)

- Problem: High-risk areas (roofs, vaults, risers) need control without bottlenecks.

- Flow: A badge is scanned at the zone. The system checks if the worker has a valid permit. If yes, entry is logged and allowed; if not, access is denied. If someone holds the door too long or slips in behind another (tailgating), the area owner gets an alert.

- Result: Safer high-risk areas, fewer manual checks, and automatic records without slowing the work.

Supply management for materials (know what’s late — while it still matters)

- Problem: Deliveries arrive, but no one sees where they stalled; issues appear at install time.

- Flow: Gate scan creates a live record; yard → floor movements build a trail; late-by-X nudges the logistics coordinator before a crew stands idle.

- Result: Fewer “waiting on materials” delays; clearer look-ahead for the day’s critical path.

What to measure (so it proves itself)

- Time to locate materials during peak hours

- “Wrong place” mistakes prevented by alerts

- Response time from the SOS alert to arrival on scene

- Access exceptions resolved (tailgates, denied entries)

- Reduction in how long critical kits sit in staging before install

Rollout designed for site reality

- Walk the site: map gate, yard, crane pad, floor staging, restricted areas.

- Tag the few materials or assets that cause real delays or risk.

- Start with three rules: too long here, wrong place, SOS.

- Send alerts by role (foreman, safety, logistics).

- Validate results on one building or phase, then expand.

Takeaway: You don’t need to watch everything. You need clear signals where work and risk actually live — so crews keep moving, and so crews keep moving, and everyone returns home safely.

#ConstructionTech #RTLS #WorkerSafety #AccessControl #SupplyManagement #IndustrialIoT #DynaWo